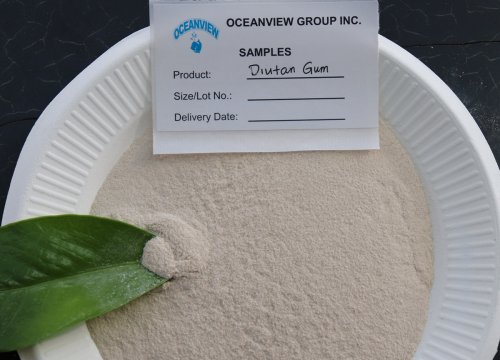

Description:

Biopolymer DG-P was developed specifically for use with cementitious materials and the newest class of superplasticizers. It enables formulators and designers to improve the performance of hardened materials by controlling flow, segregation, sedimentation and bleed. In addition, DG-P develops a higher degree of pseud plasticity, greater low shear rate viscosity (LSRV), and improved viscosity retention at elevated temperatures when compared to traditional polymeric rheology modifiers used in drilling, workover or completion fluids.

Biopolymer DG-P, analogue of Diutan gum, is a viscosity modifying agent (VMA) specifically used where super pseudplasticity characteristics are required such as cementitious materials and oil and gas drilling.